Triton Innovation

Triton Innovation provides food grade, stainless steel, and sanitary conveyors, as well as dumpers. Triton also has the ability to customize machines to get you exactly what you need.

Products

Dumpers/tippers

Homogeneous Belt Conveyors

Dumpers/tippers

Triton dumpers are versatile and efficient. They come in varying sizes and styles.

Belt Conveyors

Homogeneous Belt Conveyors

Dumpers/tippers

Triton has multiple configurations of belt conveyors, which vary based on direction of transportation of materials.

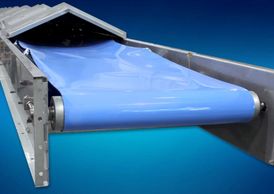

Homogeneous Belt Conveyors

Homogeneous Belt Conveyors

Modular Plastic Belt Conveyors

These belt conveyors are more sanitary, lighter weight, easier to clean, and more durable than standard belt conveyors.

Modular Plastic Belt Conveyors

Modular Plastic Belt Conveyors

Modular Plastic Belt Conveyors

These belts are extremely convenient for food plant operations. They are low maintenance, easy to clean, and customizable. They are also easy to repair, as the entire belt does not need to be replaced if damage is limited to specific sections.

Trough Conveyors

Modular Plastic Belt Conveyors

Horizontal Motion Conveyors

Trough conveyors keep materials in the center, as the sides are inclined. This design is perfect for loose and/or bulk materials, as well as long distance transportation, in order to avoid spillage.

Horizontal Motion Conveyors

Modular Plastic Belt Conveyors

Horizontal Motion Conveyors

Unlike vibratory conveyors, horizontal motion conveyors move back and forth horizontally, creating a gentler impact on the product, to reduce separation. These conveyors are easier to clean than standard ones.

Wire Mesh Conveyors

Table Top chain Conveyors

Wire Mesh Conveyors

Wire mesh conveyors can withstand extreme temperatures, maximize air flow through the belt, are corrosion resistant, and are non-absorbent.

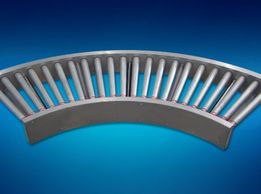

Roller Conveyors

Table Top chain Conveyors

Wire Mesh Conveyors

Roller conveyors help transport products without needing to use as much energy, and are often much quieter. Size and type of product will dictate which of the multiple roller conveyors is best for you.

Table Top chain Conveyors

Table Top chain Conveyors

Table Top chain Conveyors

Table top chain conveyors are perfect for transporting products through multiple curves, elevation changes, and multiple lanes. They are easily adaptable to many applications.

Copyright © 2024 Perkins Engineering - All Rights Reserved.

Powered by GoDaddy